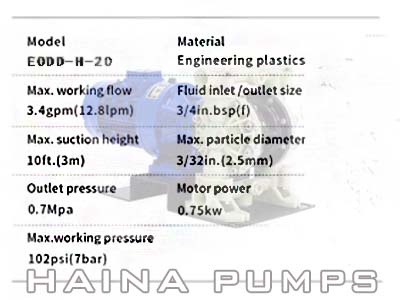

Electric Operated Diaphragm Pump Performance Parameters:

| Specifications | QBY3-20 / EODD-20 | QBY3S-20 / EODD-H-20 |

| Max.Flow | 3.4 gpm (12.8 lpm) | 3.4 gpm (12.8 lpm) |

| Max.Working Pressure | 58 psi (0.4 Mpa,4 bar) | 102 psi (0.7 Mpa,7 bar) |

| Fluid Inlet Size | 3/4 in.bsp (f) | 3/4 in.bsp (f) |

| Fluid Outlet Size | 3/4 in.bsp (f) | 3/4 in.bsp (f) |

| Max.Suction Height(dry suction) | 10 ft. (3 m) | 10 ft. (3 m) |

| Max.Permitted Grain | 3/32 in. (2.5 mm) | 3/32 in. (2.5 mm) |

| Every Reciprocating Flow | 0.04 gal. (0.15L) | 0.04 gal. (0.15L) |

| Max. Reciprocating Speed | 85 cpm | 85 cpm |

| Motor power | 0.55kw | 0.75kw |

| Pump body structure | Cast steel Nodular cast iron Aluminum alloy PP Stainless steel PVDF | |

Electric Operated Diaphragm Pump Main USES:

- All kinds of highly toxic, flammable and volatile liquids.

2. all kinds of strong acid, strong base, strong corrosive liquid.

- Medium with high temperature can be transported to 150℃.

4. as a variety of filter press front stage pressure feeding device.

- Hot water recovery and circulation.

- Loading and unloading of tankers, terminals and oil products.

Pump pickle jam, mashed potatoes, chocolate, etc.

8. pump paint, gum, pigment adhesive.

9. all kinds of porcelain glaze slurry, cement grouting, mortar, mud.

10. all kinds of rubber latex, organic solvents, fillers.

- Drain sewage and remaining oil from the bunker by pump for tanker barge clearance.

12. hops and baking powder pulp, syrup, molasses.

- Pump and suck sewage and sediment from mines, tunnels, tunnels and sewers.

- Suction of various special media.

Electric Operated Diaphragm Pump Performance characteristics:

- No irrigation and water diversion is required, and the self-absorption capacity is up to 7 meters.

2, through the performance is good, the diameter of less than 10 mm particles, mud, etc. can pass effortlessly.

3, because the diaphragm will be delivered medium and drive mechanical parts separate, so the medium will never leak out. And pump itself without shaft seal, the service life is greatly extended. According to different media, the diaphragm can be divided into neoprene rubber, butadiene rubber, fluororubber, tetrafluorin, etc., can completely meet the requirements of different customers.

4, the pump body medium flow part, according to user requirements, can be divided into cast iron, stainless steel, PP,

Polypropylene,PVDF,aluminum alloy, motor is divided into ordinary type and explosion-proof type two.